-

Dupont XPS 150 Blue Board - All Sizes

Vendor:DupontfromRegular price $29.03Sale price $29.03 Regular priceUnit price per$0.00 -

Kingspan GreenGuard GG25-LG XPS 4ft x 8ft Insulation Board - All Sizes

Vendor:KingspanfromRegular price $2,697.45Sale price $2,697.45 Regular priceUnit price per$0.00 -

Dupont XPS 250 Blue Board - All Sizes

Vendor:DupontfromRegular price $29.67Sale price $29.67 Regular priceUnit price per$0.00 -

Owens Corning FOAMULAR 250 XPS Insulation Board - All Sizes

Vendor:Owens CorningfromRegular price $43.55Sale price $43.55 Regular priceUnit price per -

Kingspan GreenGuard GG40-LG XPS Insulation Board - 2in x 4ft x 8ft - (48 Boards)

Vendor:KingspanRegular price $4,197.50Sale price $4,197.50 Regular priceUnit price per$0.00 -

Owens Corning FOAMULAR NGX 250 4ft x 8ft Insulation Board

Vendor:Owens CorningfromRegular price $52.55Sale price $52.55 Regular priceUnit price per -

Kingspan GreenGuard GG25-LG XPS Insulation Board - Shiplap Edge - All Sizes

Vendor:KingspanfromRegular price $2,697.54Sale price $2,697.54 Regular priceUnit price per$0.00

What is XPS foam insulation?

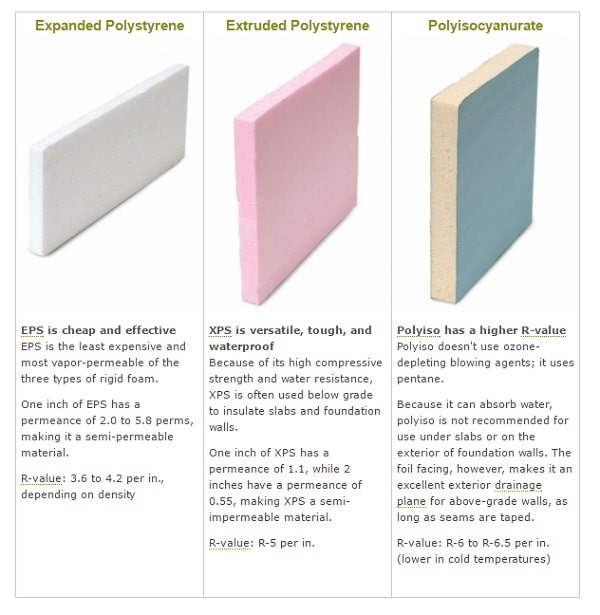

Extruded Polystyrene, referred to as XPS insulation, is a closed-cell insulation product commonly used in remodeling and new construction applications. Due to the manufacturing process, polystyrene board insulation is typically available only in standard dimension square or rectangular boards. Brands of XPS rigid insulation are generally recognizable by the color of the insulation: blue made by Dow, pink made by Owens Corning, green made by Kingspan, etc.

Extruded polystyrene (XPS) foam is rigid foam providing a strong, yet lightweight and flexible insulation solution that is resistant to water absorption, making it ideal for a range of building and commercial applications.

What is rigid foam insulation?

Extruded polystyrene (XPS) foam is rigid insulation that's also formed with polystyrene polymer, but manufactured using an extrusion process, and is often manufactured with a distinctive color to identify product brand.

Where can rigid foam board insulation be used?

Domestic and Commercial application areas for Extruded Polystyrene (XPS Foam) is as follows

- Cavity walls

- Decks

- Underwalls

- Over truss or Between rafters

- Suspended ceiling

- Inverted roofs

- Floors and Balconies.

The use of Extruded Polystyrene Foam insulation in commercial and residential buildings offers great flexibility, compatibility, and thermal efficiency for use in all areas of a building envelope.

Extruded Polystyrene Board is ideal for a range of uses – from wall and ceiling insulation, cool rooms & refrigeration, under the concrete slab (i.e. car park), and even for architectural modeling or hobby model making.

Is XPS insulation a vapor barrier?

Extruded Polystyrene (XPS Foam) has a perm rating of around 1, making it semipermeable. Thicker faced XPS is stronger and can have a lower perm rating, but it is still considered a vapor retarder, not a vapor barrier.

What is the R-Value of XPS Foam Insulation?

Extruded polystyrene (XPS) likewise improves with colder temperatures. Its nominal R-value is 5 per inch. This is the foam you see used a lot for exterior wall sheathing. It's generally blue (Dow) or pink (Owens-Corning). Extruded Polystyrene Foam will off-gas and lose some insulation performance over time - especially below-grade and when tested in real-world applications.

What is the difference between pink and blue foam insulation boards?

Both pink and blue xps foam insulation are rigid insulation panels made from extruded polystyrene. The chemical composition, manufacturing process, and insulating capability of the two products are similar and the principal difference between them is that they are manufactured by two different companies.

Pink foam board is manufactured by Owens Corning, and it's marketed under several different brand-specific product names, including Foamular, Propink, Thermapink, and Insulpink. Blue foam board is manufactured by Dow Chemical Co., and it's marketed under the Styrofoam brand name.

What are the benefits of polystyrene foam insulation?

- Lower heating and cooling Cost

- Versatility

- Won’t support mold or mildew growth

- Environment friendly

- No Leaks

- Endurance

When using Extruded Polystyrene Insulation (XPS), it is very important to install the product properly, as incorrect installation or exposed areas are violations of many building codes.

Extruded Polystyrene Board vs eps insulation

- Pros: Stronger and more water-resistant than EPS, better for below-grade applications

- Cons: Most products include strong chemical flame retardants. The blowing agents used will deplete the ozone layer

- R-Value: 5 per inch

- Cost: $0.61 Ex Vat per square foot for one-inch thickness

Above grade Extruded Polystyrene Insulation foam acts as a vapor retarder. When Extruded Polystyrene Insulation is taped it can act as an air barrier. The manufacturers and standardized testing state that it does not absorb moisture, nor is it affected adversely by it.

| Property | Test Method | Value |

Thermal Resistance3, R-Value (180 days) minimum, hr·ft2·°F/Btu (RSI, °C·m2/W) @ 75°F (24°C) mean temperature | ASTM C518 | |

| ¾" Thickness | 4.0 (0.70) | |

| 1" Thickness | 5.0 (0.88) | |

| 1½" Thickness | 7.5 (1.32) | |

| 2" Thickness | 10 (1.76) | |

| 2½" Thickness | 12.5 (2.20) | |

| 3" Thickness | 15 (2.64) | |

| 4" Thickness | 20 (3.52) | |

| @ 40°F (4.4°C) mean temperature | ||

| ¾" Thickness | 4.3 (0.76) | |

| 1" Thickness | 5.4 (0.95) | |

| 1½" Thickness | 8.1 (1.43) | |

| 2" Thickness | 10.8 (1.90) | |

| 2½" Thickness | 13.5 (2.38) | |

| 3" Thickness | 16.2 (2.85) | |

| 4" Thickness | 21.6 (3.80) | |

Rated Excellent

Rated Excellent